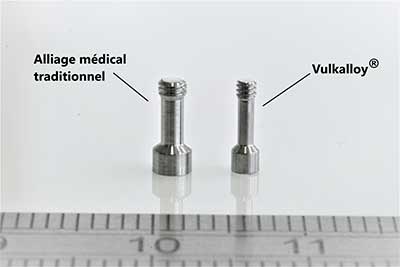

Vulkam: a SIMaP success story

The startup Vulkam was launched from the Simap* laboratory and is a growing success story. Thanks to amorphous metals with unique properties, the startup can meet emerging industrial needs and open the door for smaller components.

e innovative materials can also be of use for sectors such as aeronautics, space exploration and defense. The Vulkalloys® product range also offers flexible materials using copper for timekeeping devices as well as biocompatible zirconium alloys that are 1.5 times more resistant than titanium based materials used for miniaturized surgical components. “For example, we produce specific pliers for cataract surgeries, which count for 850,000 surgeries a year in France!” The latest Vulkalloy® to be developed by Vulkam is a nickel based alloy that is simply the most resistance material that exists! With its strength and resistance to friction, the alloy could be used in watchmaking or medical industries.

e innovative materials can also be of use for sectors such as aeronautics, space exploration and defense. The Vulkalloys® product range also offers flexible materials using copper for timekeeping devices as well as biocompatible zirconium alloys that are 1.5 times more resistant than titanium based materials used for miniaturized surgical components. “For example, we produce specific pliers for cataract surgeries, which count for 850,000 surgeries a year in France!” The latest Vulkalloy® to be developed by Vulkam is a nickel based alloy that is simply the most resistance material that exists! With its strength and resistance to friction, the alloy could be used in watchmaking or medical industries.