In late November 2021, the CNRS organised a communication event based around its joint laboratories, at Palais Brogniart in Paris. Minister for Higher Education, Research & Innovation Frédérique Vidal cited the exemplary success of the Flux software suite, a result of the work of G2Elab (CNRS, Grenoble INP – UGA, UGA). 40 years ago, this software entered the industrial world, and it is now marketed by Altair Engineering, an international leader in engineering simulators with a joint laboratory with G2Elab.

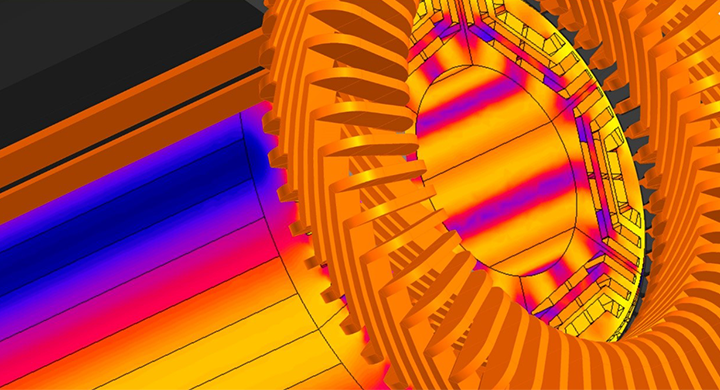

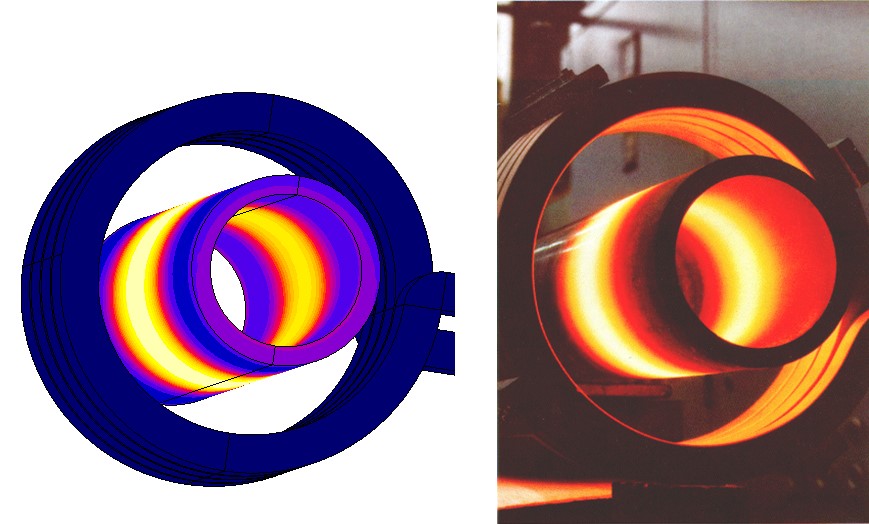

With 2,000 users across 750 industrial sites, Flux is currently the third biggest program in the world for simulating low-frequency electromagnetic fields. Engineers use it to simulate electromagnetic fields produced by all kinds of electrical devices. “

Electrical machines convert electric energy into mechanical energy,” explains Olivier Chadebec, CNRS researcher at G2Elab. “

This conversion relies on a kind of intermediate energy, electromagnetic energy, which is important to quantify in order to evaluate the performance of the machine. The simulation software makes it possible to construct a digital copy of the machine and calculate the low-frequency electromagnetic fields that it generates, without having to actually build it. This makes it possible to make as many adjustments to the parameters as needed, before making the machine in real life.”

This kind of software is useful for everything related to converting electrical energy - particularly in the transport sector (planes, trains, cars, etc.) but also for all kinds of sensors and actuators, power plant generators, etc. The market is very rich!

Software in perpetual evolution

Far from resting on its laurels, the Flux software (which uses finite element method) is constantly the subject of multiple theses at the laboratory. The devices to be simulated are increasingly complex and use increasingly elaborate materials. Furthermore, it is important to be able to obtain ever-more precise and fast results (high-performance calculation). In recent years, innovations have notably made it possible to optimise 3D calculations, to speed things up while maintaining optimal precision. “Currently, at the laboratory, we are working on models for magnetic materials, which are especially hard to model,” indicates Olivier Chadebec. “

We are also optimising topologies, to guide engineers in creating new, more adapted kinds of motors. Lastly, we are working on original modelling methods, such as the integral equation method, and performing parallel calculations.”

The collaboration between Altair Engineering and G2Elab has also given rise to the program FluxMotor, which is used to build electrical machines as well, but functions more simply than Flux.

Altair Flux™ ©1983-2021, held by Altair Engineering Inc.

photos credits:

Altair Flux en 2D, Skew et 3D. Altair Flux™ ©1983-2021, held by Altair Engineering Inc.